Well Pump Repair & Well System Installation

Frequently Asked Questions

Check for power

- Breakers – turn the breaker off then back on.

- Fuses – replace with new and keep the old ones they may still be good.

Check pressure switch to see if contacts are touching (TURN POWER OFF FIRST!)

- If they are then your pump should be running – you likely have a problem down the well and should call for service.

- If the contacts aren’t touching then

- You might need a new pressure switch

- If you have a lever on the side of your switch move the lever to the run or on position and hold until the pressure reaches 25psi

- Your pressure switch might be frozen in the off position

- Some of the piping around the pressure switch might be clogged and it can’t get an accurate reading.

- If you have a deluxe control box you might have reset buttons on the underside of the box that might have tripped. Press these firmly to reset them.

To check to see if your pressure tank needs charged or replaced first turn off the power to the pump. You can do this by flipping a breaker or there might be a disconnect box near your pressure tank. Once the power is off, run a few faucets to drain your system and then you can check the pressure. The pressure in your tank should be two pounds lower than your cut in pressure on your pressure switch. For example – if your system turns on at 40 pounds and builds up to 60 pounds before shutting off, then your tank should be around 35 – 38lbs. check to see if your tank is waterlogged by giving it a push, an empty tank should be light enough to shake. If you hear water slosh around or it’s too heavy to move at all you likely need a new tank.

Your pump is running all the time this could be because

- Your pump is worn and can’t build up enough pressure to shut off

- You have a leak somewhere and that’s preventing the system building up to pressure.

- Your pump is running all the time this could be because

- Your pump is worn and can’t build up enough pressure to shut off or

- You have a leak somewhere and that’s preventing the system building up to pressure.

- Check your pressure tank – you could have low pressure if your tank is bad or improperly charged.

- You might have a leak somewhere and that’s preventing the system building up to pressure. This could be water use in your home as well.

- Your pump is worn and is not moving the amount of water it used to.

- You might have a bad pressure tank – If your tank is waterlogged the pressure switch will click on and off because the area in the tank it can actually fill is much smaller than it should be. Any time you run a tap your pump will turn on again, replace the tank.

- You might have a leak – This will prevent the pressure from holding in your tank and it will slowly bleed off until your pressure switch calls for water again.

- Something in your home could be using water – A water filtration system might be malfunctioning, or you might have a toilet that never shuts off etc.

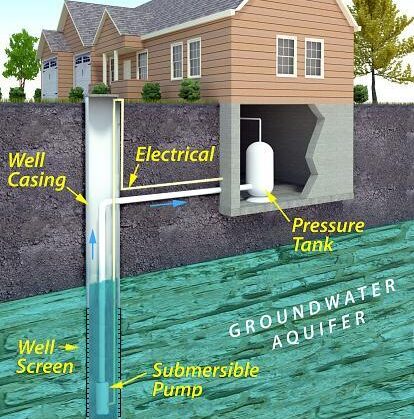

Water pumps can actually either be Submersible pumps. Typical failures impeller issues in the pump end or motor failures. There are three or four different motor types, but all are sealed from any kind of water intrusion. A pump has the expected life of 100,000 miles without any issues, this means it could fill 110 average size swimming pools in its lifetime.

Water pumps use a unitized seal and a ceramic seal to support the shaft and provide protection to the coolant from leaking around the shaft. Sometimes pumps also fail to work due to the contaminants that circulate with the coolant as they are abrasive enough to act against the seal. The pump should be replaced as soon as you see the first sign of coolant leaking around the shaft. If you have more questions for well pump repair in Western North Carolina check out our Frequently Asked Questions answering many of the typical questions about WNC water well systems.

Most of the problems are due to corrosion and the coolant system. Calling an expert water pump service provider in Western North Carolina will help you with this problem. He will thoroughly drain the cooling circuit before installing a new water pump because the coolant should be replaced with the correct manufacturer’s recommended coolant. Nowadays the coolant system is more complex than as it once was and involves a lot of components made of different materials. The need to get the manufacturer-approved coolant is because they protect the components from corrosion and rust.

- No power or incorrect voltage: Check voltage at line terminals. The voltage must be ± 10% of rated voltage. Contact Power Company if voltage is incorrect.

- Fuses blown or circuit breakers tripped: Check fuses for recommended size and check for loose, dirty or corroded connections in fuse receptacle. Check for tripped circuit breakers. Replace with proper fuse or reset circuit breakers

- Defective pressure switch: Check voltage at contact points. Improper contact of switch points can cause voltage less than line voltage. Replace pressure switch or clean points.

- Control box malfunction: Repair or replace.

- Defective wiring Check for loose or corroded connections or defective wiring: Correct faulty wiring or connections.

- Bound pump: Check for misalignment between pump and motor or a sand bound pump. Amp readings will be 3 to 6 times higher than normal until the overload trips. Pull pump and correct problem. Run new installation until the water clears.

- Defective cable or motor: Repair or replace.

Pressure switch: Check setting on pressure switch and examine for defects. Reset limit or replace switch.

- Check valve – stuck open: Damaged or defective check valve will not hold pressure. Replace if defective.

- Waterlogged tank: Check air charge. Repair or replace.

- Leak in system: Check system for leaks. Replace damaged pipes or repair leaks. Possible Cause Checking Procedures Corrective Action

- Pressure switch: Check switch for welded contacts. Check switch adjustments. Clean contacts, replace switch, or adjust setting.

- Low water level in well: Pump may exceed well capacity. Shut off pump, wait for well to recover. Check static and drawdown level from well head. Throttle pump output or reset pump to lower level. Do not lower if sand may clog pump.

- Leak in system: Check system for leaks. Replace damaged pipes or repair leaks.

- Worn pump: Symptoms of worn pump are similar to those of drop pipe leak or low water level in well. Reduce pressure switch setting, if pump shuts off worn parts may be the fault. Pull pump and replace worn parts.

- Loose coupling or broken motor shaft: Check for loose coupling or damaged shaft. Replace worn or damaged parts.

- Pump screen blocked: Check for clogged intake screen. Clean screen and reset pump depth.

- Check valve stuck closed: Check operation of check valve. Replace if defective.

- Control box malfunction: Repair or replace